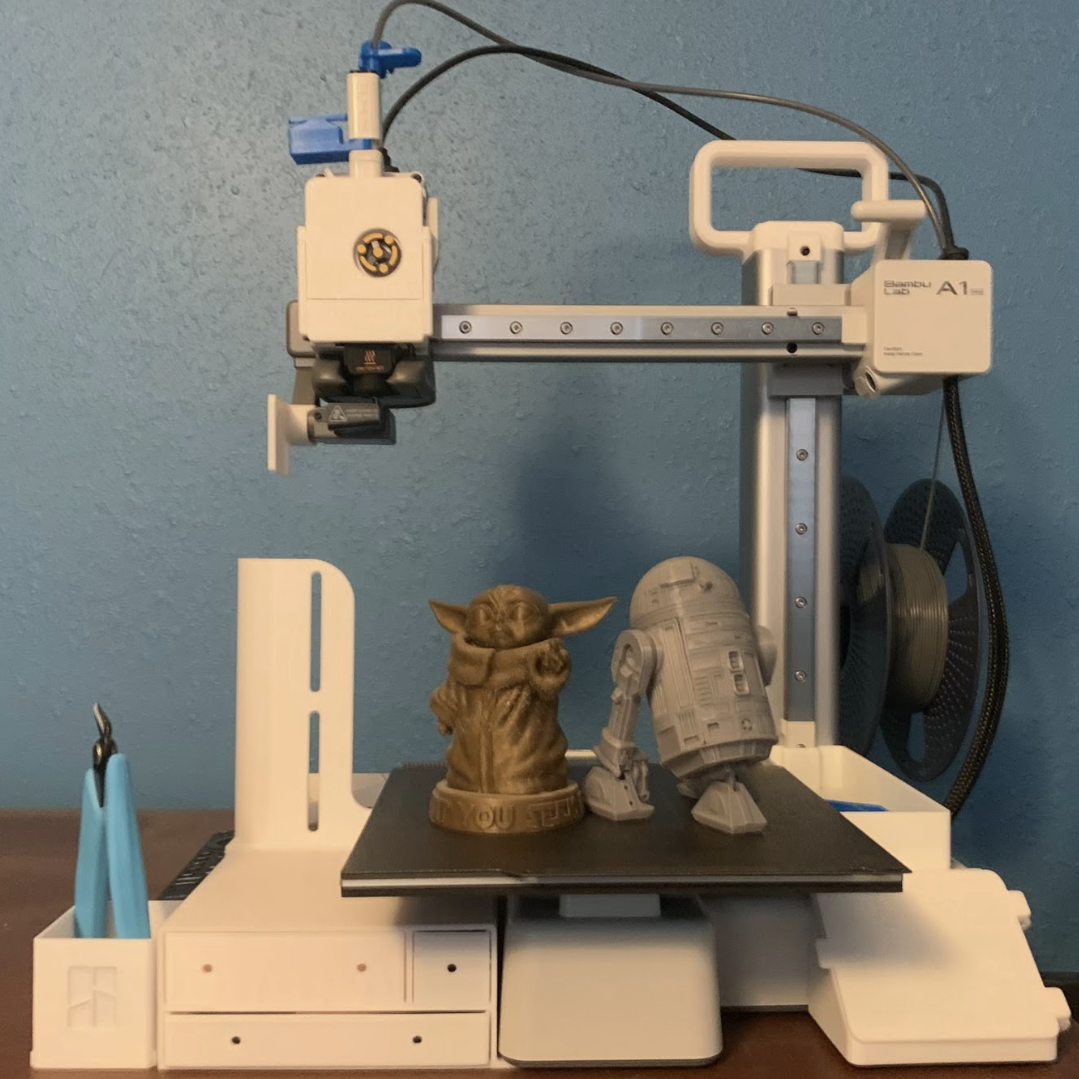

After hours of waiting, sophomore Asher Bertulfo carefully pries his 3-D printed creation from the printer, a model of R2-D2 from Star Wars. As he picks it up, he observes the details, the intricate panels that allow the model to move, and the other components that he spent hours creating.

In the past year, Bertulfo has learned to make larger and more detailed designs by spending more time designing and working on his projects as he improves. As he progressed on his 3-D printing journey, his friends observed a change within him.

“I’ve noticed that he’s been more dedicated to his work and has been putting a lot more research into just learning the types of filaments you have to use to print certain types of designs. Over the past year, I’ve just seen him using more of his personal free time to work on projects,” sophomore David Topete said.

His most recent project took more than 12 hours to make. However, the 3-D printing process doesn’t always go as planned. According to Bertulfo, the filament, a material used to print designs, travels along a tube that once melted into a soft and moveable material goes into a part called the extruder where the filament goes along a path programmed by the designer.

“For example, this one time, when I was making a sci-fi plane, the filament got jammed inside the extruder, and so when I went home to see how it printed, I realized what had happened,” Bertulfo said. “I had to manually take out the extruder, clean it out and then put it back in. When things like that happen, I can get burned out with the amount of time it takes to fix it.”

With inspiration from his father, Bertulfo started 3-D printing in the summer of 2023. When he first picked up 3-D printing, Bertulfo printed small boats and figurines. However, with the introduction of his new and faster 3-D printer, the Bambu A1 Mini, he has started making better prints, such as sci-fi ships, swords and a moveable model of R2-D2.

“Ever since I was young, I’ve been obsessed with Legos since building Lego sets has just really fueled my creativity,” Bertulfo said. “I hope to make bigger ships, planes and more. I’m also considering buying more 3-D printers so that I can have multiple and work on multiple projects simultaneously.”

After his 3-D printing experience, Bertulfo aspires to pursue it in the future as a career, either in aeronautics or in space.

“I know 3-D printing is going to be helpful when designing plans and parts for anything space-related since it’ll be cheaper and more effective,” Bertulfo said. “It’s a field of engineering that’s not as well known, but that could do so many things for our world. I’ve been so interested in that, and that’s honestly what made me want to continue learning.”